Genuine Automation Parts | Worldwide Express Delivery | 12-Month Warranty — [GET A QUOTE]

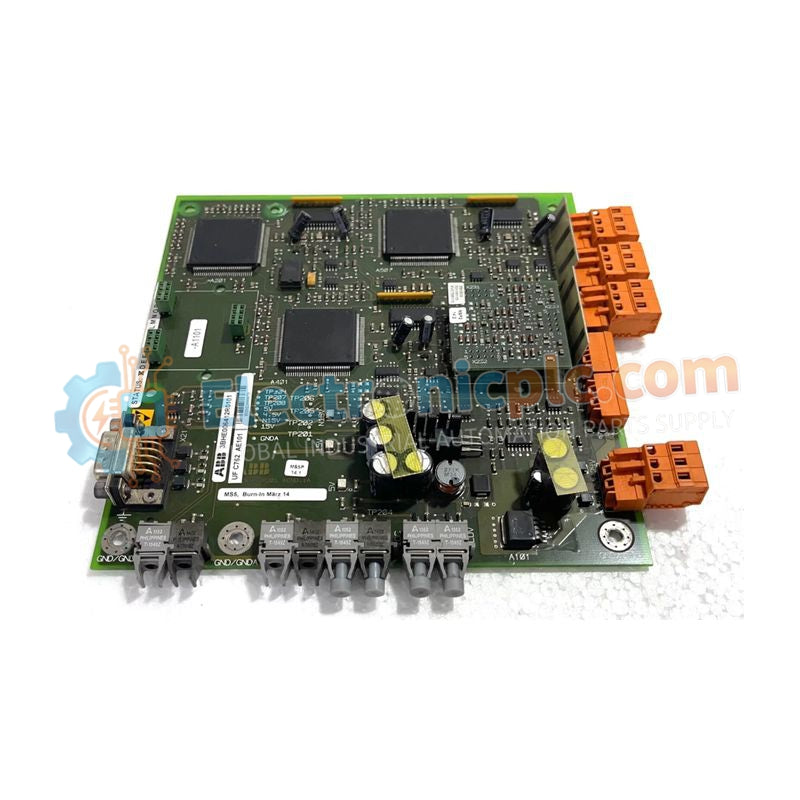

The UF C762 AE101 (3BHE006412R0101) is a high-precision Control Voltage and Measurement Interface (CVMI) printed circuit board manufactured by ABB. It is specifically engineered for use in power electronics and excitation systems, functioning as a critical measurement interface within complex drive and excitation control loops.

This variant features professional-grade conformal coating, providing enhanced protection against moisture, dust, and chemical contaminants. This protection is essential for maintaining signal stability and long-term reliability in harsh industrial environments.

Please note that this assembly is supplied as the base carrier board only and does not include SVA (Voltage Adapter) or SCA (Current Adapter) sub-prints. These modules must be installed separately to configure voltage and current measurement scaling according to system requirements.

| Specification | Description |

|---|---|

| Part Number | 3BHE006412R0101 |

| Type Designation | UF C762 AE101 |

| Functional Role | CVMI (Control Voltage Measurement Interface) |

| Protection | Conformal coated for environmental resilience |

| Weight | 0.3 kg |

| Sub-print Requirement | Requires SVA and SCA modules for full measurement functionality |

| Application Environment | High-power converters, excitation systems (UNITROL), industrial drives |

| System Integration | Compatible with ABB PEC (Power Electronic Controller) platforms |

The UF C762 AE101 is commonly deployed in:

ABB UNITROL excitation systems

High-power industrial converters

Large synchronous motor and generator control systems

Heavy-duty industrial drive platforms

Its role is to acquire and condition high-level voltage and current signals from the field, converting them into stable, processable inputs for the primary control processor within the PEC architecture.

Does this board come ready for immediate measurement?

No. The UF C762 AE101 is delivered without SVA and SCA sub-prints. These must be transferred from an existing board or ordered separately to complete the measurement circuit configuration.

What is the benefit of the “Coated” designation?

The conformal coating protects PCB traces from corrosion, conductive dust, and moisture-induced dendrite growth. This significantly improves long-term reliability in high-humidity, marine, or metal-processing environments.