Genuine Automation Parts | Worldwide Express Delivery | 12-Month Warranty — [GET A QUOTE]

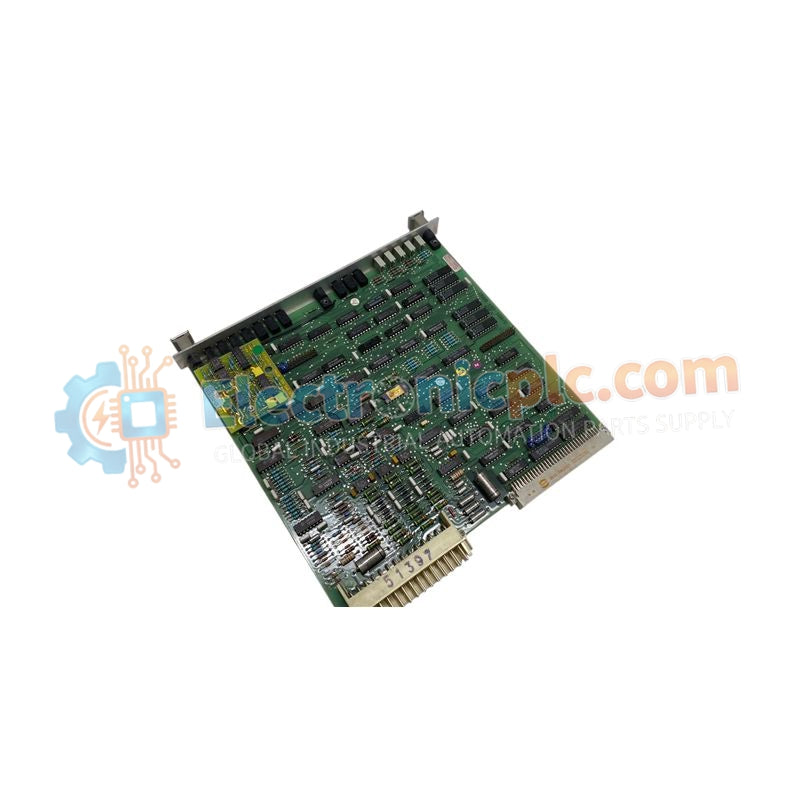

The DSQC104 (6369901-104) is a dedicated resolver interface board designed for ABB industrial robot controllers.

This module functions as the critical feedback interface between the robot’s servo motors and the control system, converting analog sinusoidal resolver signals into high-resolution digital position data. It enables precise angular position detection for each robotic axis, ensuring accurate motion control and synchronization.

Engineered for harsh robotic environments, the DSQC104 is resistant to electrical noise, vibration, and thermal stress commonly present in robotic cells. It plays a key role in maintaining path accuracy, axis stability, and calibration integrity within ABB S3 and early S4 controller platforms.

The board performs high-speed resolver-to-digital conversion (RDC), allowing real-time position processing essential for multi-axis coordinated motion.

| Specification | Description |

|---|---|

| Part Identification | DSQC104 |

| Ordering Number | 6369901-104 |

| Module Function | Resolver-to-Digital Conversion (RDC) |

| Controller Compatibility | ABB S3 / Early S4 Robot Controllers |

| Axis Support | Multi-axis (typically up to 6 axes) |

| Resolver Excitation | Optimized for ABB standard resolver units |

| Mounting Type | Card-rack / Backplane integrated |

| Dimensions (L × W × H) | 25.4 cm × 25.4 cm × 2.5 cm |

| Weight | 0.4 kg |

| Manufacturing Origin | Sweden |

The DSQC104 is primarily used in:

Maintenance of legacy ABB IRB robots

Automotive spot welding cells

Material handling systems

Palletizing and packaging lines

Production lines operating S3 or early S4 controllers

It is an essential OEM spare part for maintaining accurate resolver feedback and ensuring continued operational reliability in legacy robotic systems.

What are typical symptoms of a failing DSQC104 board?

Common indicators include:

Resolver-related alarm messages

Erratic or unstable axis motion

Frequent loss of revolution counters

Simultaneous feedback errors on multiple axes

If multiple axes report resolver faults, the DSQC104 is often a primary diagnostic focus.

Is calibration required after replacement?

The board itself does not require hardware calibration. However, after installation, the robot typically requires fine calibration or revolution counter synchronization to align the electronic feedback with the mechanical zero positions of each axis.